Today, Dycron manufactures 2100 tonnes Food Colours on an annual basis. With entire system closely monitored at each critical points. The periodical equipment calibration and internal audits ensures highest yield and quality product for our customers.

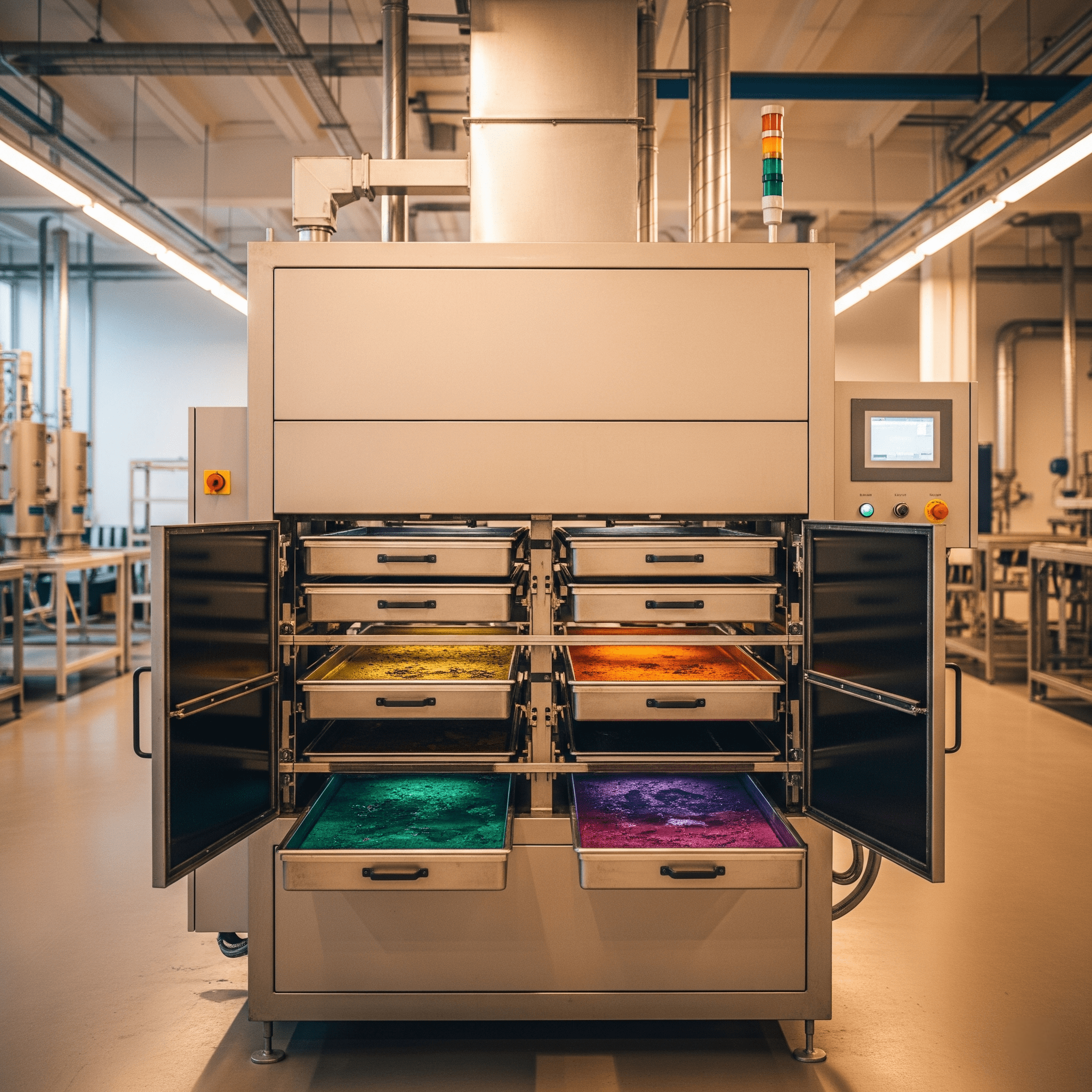

Our advanced manufacturing technologies includes ultra-filtration; reverse osmosis and micro-filtration and with the reliable drying methods like Spray Drying and Tray Drying technology installed we ensure faster and on-time delivery with desired appearance of the product. Our processes have been developed after intense research and development for using innovative methodologies to create cost-effective, time efficient and high-quality products.

Each batch produced undergoes stringent quality checks and labelling by which we monitor them and ensure batch traceability. Our manufacturing processes have evolved to the point where we ensureflexibility in production management to respond immediately to specific customer needs.

Our products are offered with different packing options in –

- 100 gms

- 500 gms

- 1 Kg Jars

- 5 Kg Jars

- 25 Kg Carton Box

- 25 Kg Paper Bags with plastic lining

- 25 Kg HDPE Drums

Custom packing options available based on customer request

The packaging ensures easy flow of material on use.

All the processes are executed as per the ISO standards for optimum results in terms of quality and production. We hold the ISO 9001:2015 certificate to attest that we follow international best practices in manufacturing and supplying food colours at our plants.

Our process

Research & Development

Continuous innovation through advanced lab testing

Focus on both synthetic and natural colour solutions

Raw Material Sourcing

Carefully selected, food-grade certified ingredients

Verified suppliers with strict quality benchmarks

Precision Manufacturing

Automated production systems

Adherence to GMP and hygiene standards

Quality Testing

Multi-stage inspection for color strength, stability & purity

In-house labs with modern analytical tools

Packaging & Labeling

Safe, compliant, and export-ready packaging

Clear batch traceability and certifications

Storage & Logistics

Temperature-controlled, hazard-free warehousing

Timely delivery through trusted distribution partners

Customer Support & Feedback

Dedicated service for technical queries and orders

Feedback-driven improvements and custom solutions

- Technologies Used

Machinery

At Dycron Colour Chem, we operate with advanced, fully-equipped manufacturing machinery that ensures precision, consistency, and high-quality output in every batch. Our facility includes stainless steel reactors, high-speed mixers, spray and tray dryers, advanced filtration units, and automated packaging systems—all designed to maintain purity, enhance efficiency, and meet global food safety standards. This robust infrastructure enables us to produce food colorants that are uniform, safe, and suitable for a wide range of industrial applications.

Automation

At Dycron Colour Chem, we leverage advanced machinery and semi-mechanized systems to ensure manufacturing excellence. While full automation is not standard in our industry, we have integrated key equipment across various stages of production including raw material handling, chemical processing, drying, blending, and packaging. These machines help improve operational efficiency, reduce manual errors, enhance safety, and maintain consistent product quality. Our focus on equipment-driven precision enables us to meet large-scale demands while adhering to the highest standards of hygiene, quality, and regulatory compliance.

Compliance & Safety Practices

At Dycron Colour Chem (P) Ltd., we prioritize safety, quality, and compliance in every stage of our production. Our facilities are ISO 9001:2015 certified and approved by Halal and Kosher standards, ensuring our food colours meet global regulatory requirements. We use only food-grade, non-toxic ingredients and follow strict quality checks to guarantee purity and consistency. Our operations adhere to Good Manufacturing Practices (GMP), and we maintain full traceability from raw material to final product. We are also committed to environmental safety through responsible waste management, safe chemical handling, and regular worker safety training. With Dycron, you can trust that every product is safe, certified, and made with care.

Contact for Custom Manufacturing

Whether you have a question or need to find a local distributors, we're here to help.

Contact Us